Technologies

Laser Etching/Engraving

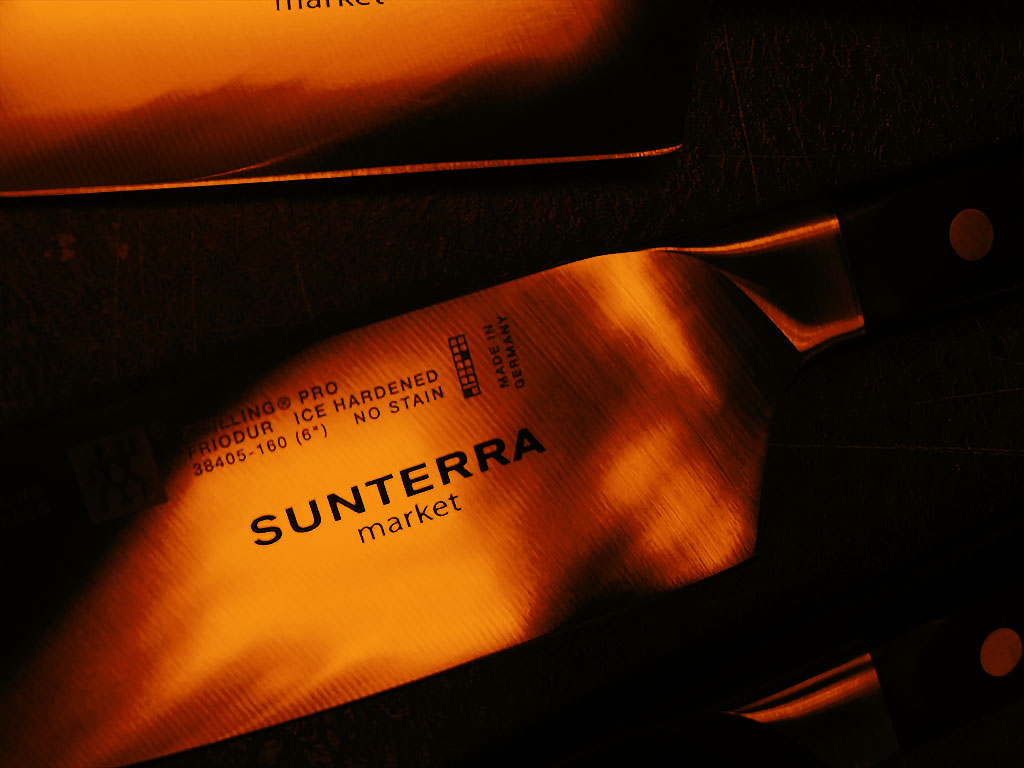

Company Branding + Marketing With Striking Clarity

Serialized Part Numbers

Control + Inlay Panels

Company Branding + Marketing With Striking Clarity.

Technologies

Laser Etching/Engraving

Laser marking is commonly applied to anodized aluminum, powder-coated parts, and stainless steel. The marking lasts as long as the material itself, never fading, chipping, scraping off or eroding.

Lasercraft provides cost-effective methods to mark metal products or components. Whether you require high volume or elaborate custom industrial prototyping we offer solutions to meet your needs.

Laser engraving is often synonymous with Laser etching, a surface marking technique where color changes occur during charring, partial melting, and chemical/molecular alterations are made to material using a concentrated laser beam in a non-contact marking process.

This technique, while in some cases uses pastes and other chemicals to enhance the effects of laser marking, does not typically involve the use of inks or tools bits that may otherwise contact or permanently damage the engraving surface.

The advantages of such a process enables us to mark objects, items, or materials that are sensitive and delicate, where structural integrity is essential to their functionality, or aesthetic qualities are meant to be preserved.

Applications

- Industrial tags, labels, and plates.

- Control and inlay panels.

- Serialized tags.

- Name tags.

- Part marking and identification.

- Tools, parts, and miscellaneous equipment.

- Directional and wayfinding signage.

- Metallic mugs, tumblers, bottles, and mugs.

- Badges

- Trophies and awards.

- Metal Knife Blades.

- Wooden knife handles.

- Wooden charcuterie and cutting boards.

- Promotional items.

- Corporate and personal gifts.

- Wood and cork coasters

- Custom wood board games and art pieces

- Leather wallets, books, and labels/tags