Where Precision is an Art

Precision Engraving, Marking + Cutting

LASER CUTTING TECHNOLOGIES

Signage to impress

Laser Etching/Engraving Technologies

Trophy Plaques + Awards

ROTARY (DEEP) ENGRAVING TECHNOLOGIES

Engraving For Commercial + Industrial Applications

Laser Etching/Engraving TECHNOLOGIES

Elevate wood products with laser etching

Laser Etching/Engraving TECHNOLOGIES

Customized Items For Gifts + Marketing

About

Lasercraft Where Precision Is An Art

Lasercraft has been servicing North American customers for all their marking and cutting needs since 2004.

Our approach reflects that of the traditional craftsman, utilizing our skills and knowledge to provide high quality products and services for projects ranging in all scopes and sizes.

Working one-on-one with our customers, our focus and attention to detail ensures that all project requirements are met, while offering customized solutions to potential challenges.

We look forward to making your next project a remarkable success!

Technologies

Laser Etching/Engraving

Never fading, chipping, scraping or eroding, our laser etching techniques will last as long as the item or material being marked. Whether applying a special reactive paste or lasering directly onto powder-coated or anodized products, laser etching is a reliable, cost-effective, and permanent marking solution.

Compared to other labeling and marking methods, the added benefit of this technology is the accurate and high level of detail only achievable through the use of laser systems.

Whether marking a small personalized gift, higher volumes of commercial items for promotional purposes, or large scale industrial components subjected to rigorous conditions, you can count on Lasercraft to provide outstanding quality within the marking industry.

Technologies

Laser Cutting

Lasercraft brings a new dimension to the production of all your signage, labelling, and wayfinding needs. Elevate your projects with signage that impresses!

Our laser systems can cut virtually any (2D) shape from a multitude of soft materials, primarily acrylic plexiglass and lamacoid plastics, with thicknesses ranging from paper-thin to 12mm (1/2”).

Considering the versatility and applications provided by modern plastics, the possibilities for what we can produce are endless!

Technologies

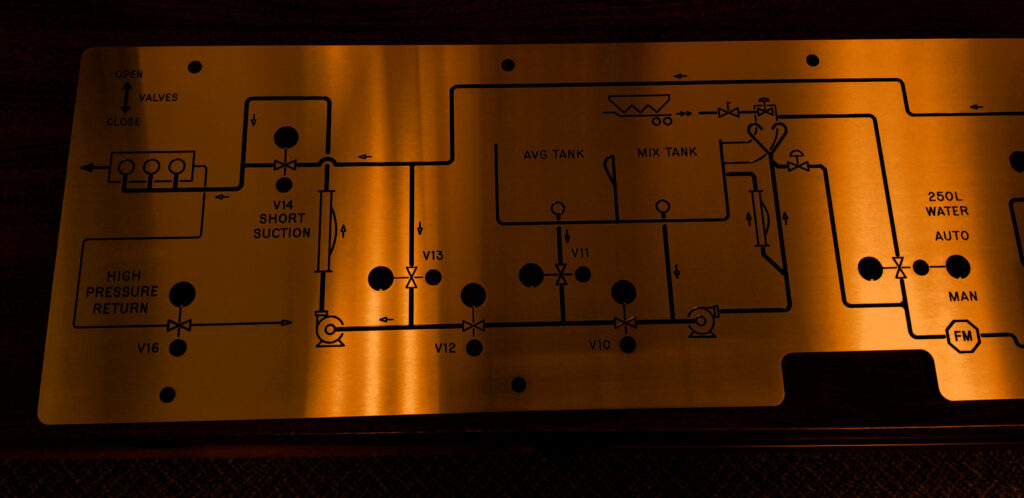

Rotary (Deep) Engraving

During the rotary engraving process, a carbide cutter moves over the surface of an item or piece of material. The rotary motion of the cutter removes one or more layers of the material. Metal surfaces are particularly well suited for rotary engraving.

Technologies

Diamond Drag Engraving

Utilizing the same equipment as Rotary (Deep) Engraving, the process of Diamond Drag Engraving is similar, but differs in two key ways:

- Rather than spinning, the Diamond-tipped

cutter remains fixed as it is dragged across the surface of the material, resulting in a crisp and fine line. - While the engraved depth is shallower than typical Rotary (Deep) Engraving, the stroke can be widened and deepened through several passes if desired.

This marking method is ideal for thinner, softer materials such as brass and aluminum, but can still be applied to the industry popular stainless steel.